Blow molding machines are mainly divided into three cat […]

Blow molding machines are mainly divided into three categories: extrusion blow molding machines, injection blow molding machines and special structure blow molding machines.

The processing technology is mainly divided into one step and two steps. At present, most bottle blowing machines are still a two-step method, that is, plastic raw materials must be made into preforms before bottle blowing. At present, pet is a commonly used environmentally friendly plastic. Blow molding machine: After the liquid plastic is sprayed out, the wind blown by the machine is used to blow the plastic body into a mold cavity of a certain shape to make a product. This kind of machine is called a blow molding machine. It is also a kind of blow molding machine, that is, hydraulic blow molding machine.

One-step and two-step blow molding machine molding processes are mainly used for PET and BOPP hollow container molding. Both have their own characteristics and are widely used. In comparison, the two-step method is more suitable for concentrated production of preforms and dispersed blown bottles; while the one-step method is more suitable for online production of beverage companies.

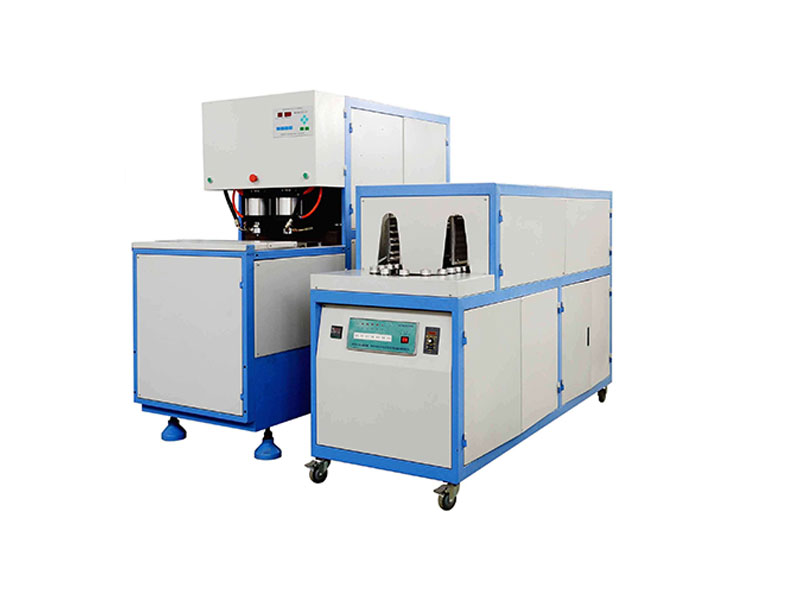

The difference between automatic bottle blowing machine and semi-automatic bottle blowing machine

There is not much difference in quality, but the bottles blown out by fully automatic machines will be slightly better than semi-automatic ones, mainly due to factors such as temperature control, timely program analysis, and fast movement transmission.

Fully automatic bottle blowing machine: high price, high output, labor saving, need better technicians to maintain. The automatic efficiency is high, and the quality is generally stable because there is no operator's influence.

Semi-automatic blow molding machine: small investment, easy operation, simple maintenance, low output, and high staff operation intensity.

There is no difference in the quality of the bottles that are blown out. The difference is the process of operation. There are more semi-automatic ones, which need to be watched by humans, and can be adjusted at any time. The automatic efficiency is high and it is only a copy.